File formats for 3D printing are typically created through CAD software and contain information about the geometry of 3D objects. It's advisable to start by learning and using common file types because they are generally compatible with most CAD programs and slicing software. This article will discuss the most common 3D printing file format types, detailing what they are, their differences, advantages, and disadvantages.

STL

STL stands for Stereolithography, which is the most common and popular file format in 3D printing. The STL file is an old file type, developed in 1987 for the first commercial 3D printer. The STL file format is widely used for the creation of simple 3D model designs and is compatible with almost all Computer-Aided Design (CAD) programs to easily generate the STL file format. Both 3D model sharing websites and 3D slicers support this type of format.

An STL file is composed of a series of small triangles to create a 3D digital model. The more triangles there are, the more accurate the model, but also the larger the file. However, it does not contain texture, color, and material data, which limits the model's design and can lead to common issues such as STL files being unable to be sliced.

OBJ

The OBJ (Wavefront OBJ) file is one of the most common file types in 3D printing. In contrast to the STL file format, OBJ has been improved to create 3D models with precision and high quality. OBJ uses not only triangles but also polygons such as quadrilaterals or hexagons to design a 3D model. Additionally, it can store data regarding geometry, colors, textures, and more. While not as common as the STL format, OBJ can be an alternative to STL because most slicers, CAD tools, and 3D printers are compatible with OBJ. Moreover, converting OBJ to STL can be achieved using these software. Programs like Blender, MeshLab, and Autodesk Fusion 360 are recommended as they can open, view, and edit OBJ file types.

AMF

The Additive Manufacturing File (AMF) format was introduced in 2011 and was initially known as "STL 2.0" with an aim to replace the STL format. The AMF 3D printer format documents can store materials, colors, and other metadata, and optional curved triangles can make smoother geometric surfaces. However, not all software and slicers are compatible with the AMF format type for 3D printing due to its slow development and lack of proper support from most 3D modeling and printing software.

3MF

The 3MF (3D Manufacturing Format) is another common file format for 3D printing, specially designed for additive manufacturing and 3D printing, as the name suggests. The 3MF format was introduced in 2015 to replace the file like .OBJ and .STL, and to simplify 3D printing. It can store all the necessary information for printing 3D models, such as units, scales, colors, meshes, materials, and texture data. Compared to the old STL files from the last century, 3MF can generate more refined and higher-standard 3D models, often with smaller file sizes. Unlike AMF, which has seen slow development and lacked support, the 3MF file format for 3D printing is gradually being widely accepted.

Which 3D Printing File Format Type Is the Best?

Each file type serves its own purpose and has its differences. If you're looking for the easiest-to-use and most commonly used 3D printer file type, STL files are the most suitable as they describe geometry using simple triangles. For color printing, OBJ files are the best choice as they can store more complex information and describe more details using polygons. Meanwhile, the 3MF and AMF 3D printing file formats incorporate the latest and most advanced technologies among these four file format types, particularly good at handling complex models with multiple colors. But, 3MF is more popular than AMF as 3MF enjoys more software support.

3D Printing Workflow

The entire 3D printing process is not as difficult as imagined, usually involving 3D modeling, 3D slicing, 3D printing, and post-processing. 3D modeling and post-processing are not necessary and can be optionally skipped. We simply explain what steps a complete 3D printing workflow includes.

3D Modeling

3D modeling is a progress that involves creating and designing a digital 3D object, typically based on CAD software or 3D scanning. Subsequently, the 3D model design can be outputted into commonly used 3D print file formats such as .STL, .OBJ, .AMF, or .3MF. 3D modeling is a skill that requires a considerable learning curve. Many 3D hobbyists may skip this step because there are numerous model-sharing websites where pre-made 3D printer files are available for free or for purchase, such as Thingiverse, Cults3D, and MyMiniFactory.

3D Slicing

Slicing for 3D printing is the process of converting a 3D model design into G-code. An unsliced file is non-printable because it lacks precise printing information. Through the print settings in a slicer software, such as layer height, print speed, temperature, infill, and other parameters, these instructions are translated into G-code. This G-code allows precise control of the 3D printer's actions and movements.

3D Printing

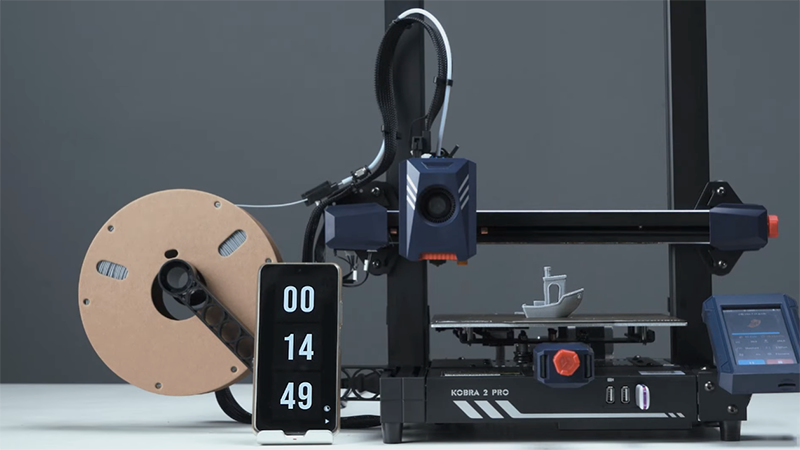

Transferring the G-code to a 3D printer, and preparing a spool of quality filament, you can start your creation. Anycubic's Kobra 2 Pro fast printer comes highly recommended as it accelerates the 3D printing process. The Kobra 2 Pro reaches speeds of up to 500mm/s, which is ten times faster than many ordinary printers. Furthermore, its advanced firmware compensates for vibrations generated during rapid printing and controls material flow to smooth the print surface. Its automatic leveling feature and a build volume of 250 x 220 x 220mm meet the needs of most 3D enthusiasts.

The final step, post-processing, is optional as everyone has different requirements. Post-processing involves removing supports, sanding, polishing, assembling, priming and painting, to ensure optimal mechanical and visual features.