Filaments are the materials used in FDM (Fused Deposition Modeling) 3D printing. They are long, thin strands that are fed into the extruder of a 3D printer. The extruder melts the filament and deposits it layer by layer to create a 3D printed object. Proper loading and unloading of filaments are essential for successful printing, while correct filament storage can extend the lifespan of the printer. If you are new to FDM 3D printing, this article will guide you step by step on how to load and unload filament on your 3D printer.

How to Load Filament on Your 3D Printer

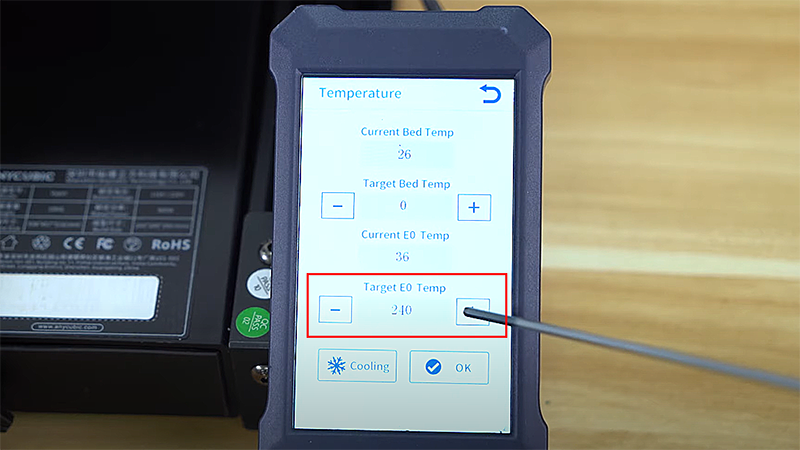

Step 1: Heat up the printer nozzle.

Through the display of your printer, find the button for preheating the nozzle. Set the nozzle temperature to the highest temperature of the filament you intend to use, and different materials require different heating temperatures. For example, the range of 190℃ - 230℃ is the optimal printing temperature for PLA filaments, so the nozzle needs to be preheated to at least 200℃.

The following table provides the recommended printing temperature settings for some popular filaments like PLA, PETG, TPU and ABS. However, temperature settings may vary slightly for consumables from different manufacturers. It is advisable to refer to the instructions provided by the manufacturer of the filament you have purchased.

| Material | Nozzle temperature (° C) | Printbed temperature (°C) |

|---|---|---|

| PLA | 190 - 230 | 60 - 80 |

| PETG | 230 - 250 | 70 - 85 |

| TPU | 210 - 230 | 40 – 60 |

| ABS | 220 - 240 | 90 - 110 |

Step 2: Prepare Filaments for printing.

Use a short-nose plier to cut the tip of the filament at a 45-degree angle. It is best to print with high-quality and dry filaments to avoid clogging the nozzle, as it may require replacing the nozzle.

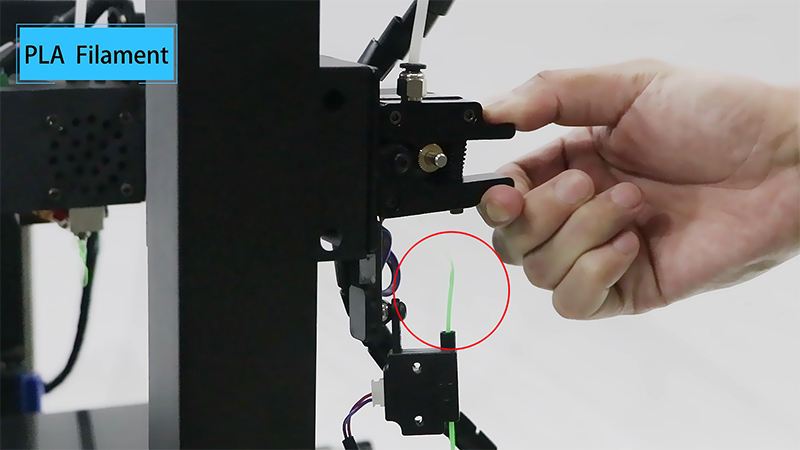

Step 3: Feed your 3D printer extruder.

If your printer is equipped with a filament runout sensor, you will need to insert the material into this sensor first. A filament sensor detects the status of the filament, and the printer will automatically pause printing when the filament runs out. For example, Anycubic Kobra 2 comes with this feature as a standard, while Kobra Neo requires an optional upgrade.

If your printer doesn't have a filament sensor, you can directly insert the filament into the extruder. However, the method of loading filament may be different depending on the type of extrusion system. If it is a direct drive, the extruder is usually connected to the print head. In this case, you will need to insert the filament into the extruder until molten filament starts coming out of the nozzle. On the other hand, if it is a Bowden extruder, you will be able to see the filament coming into the Bowden tube and then being squeezed from the nozzle. Lastly, it is necessary to adjust the extruder gear tension to avoid issues of over-extrusion or under-extrusion.

How to Unload Filament on Your 3D Printer

Manually removing a filament from the printer is very similar to the steps of loading a filament. In the first step, heat the nozzle to a higher temperature. Push the filament forward to allow any burned material inside the nozzle to melt and extrude. Finally, swiftly pull out the filament, but care is needed when unloading the strand to prevent breaking.

How to Store 3D Printing Filament

Firstly, it is important to purchase trusted and reputable brands, as they typically provide high-quality products and after-sales services. Many 3D printer manufacturers offer various filaments specifically designed for their machines. For instance, Anycubic provides not only excellent and affordable 3D printers, but also a wide range of consumables like 1.75mm PLA 3D printer filaments that are fully compatible with their own machines as well as most printers on the market.

Storing your filaments in a cool and dry place ensures successful printing. It is advisable to place them in sealed bags or containers, removing as much air as possible to prevent moisture and dust from contaminating. Because using damp or low-quality materials can result in surface defects such as 3D print blobs and stringing, and can even damage your machine. Additionally, you can make a DIY filament dust filter and put a sponge or a piece of foam into the filter helps collect dust, dirt, and residue during printing. If unluckily your filament becomes wet, there are some simple and easy ways to dry it, like using an oven, a food dehydrator, or a filament dryer box.